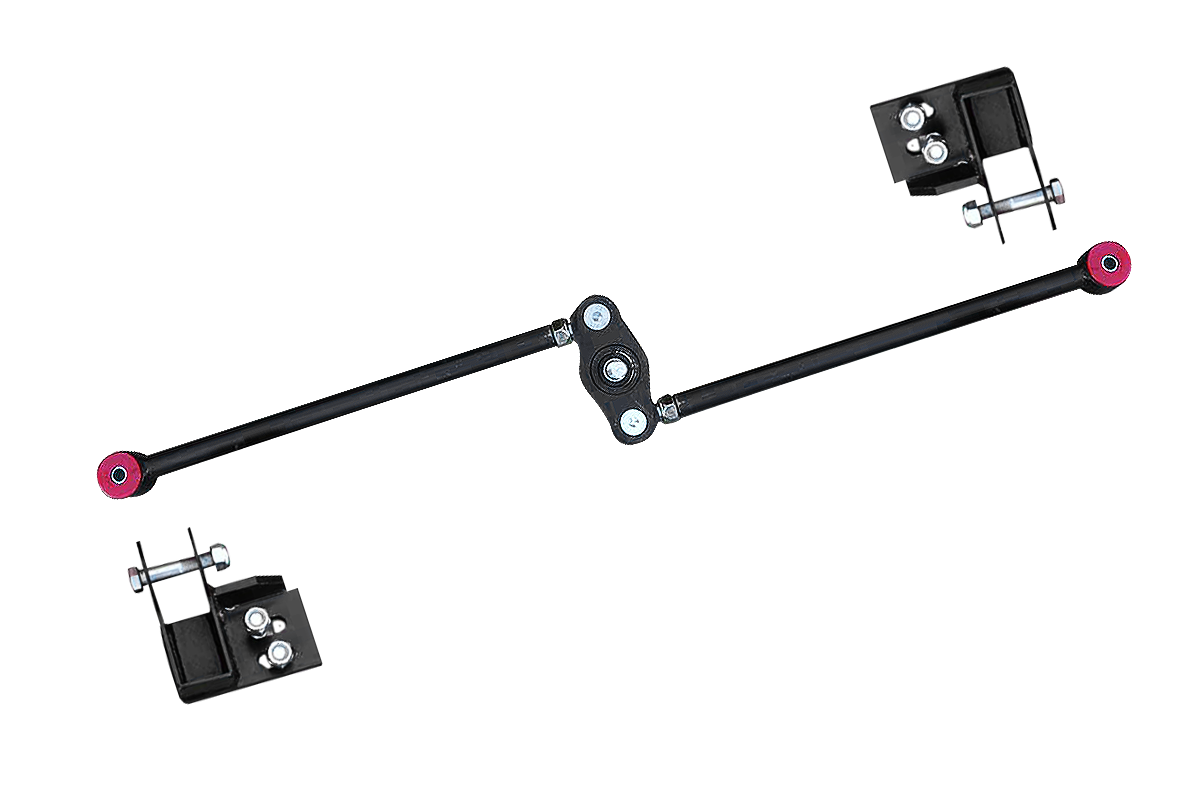

Trans-Am 3 Link Rear Suspension

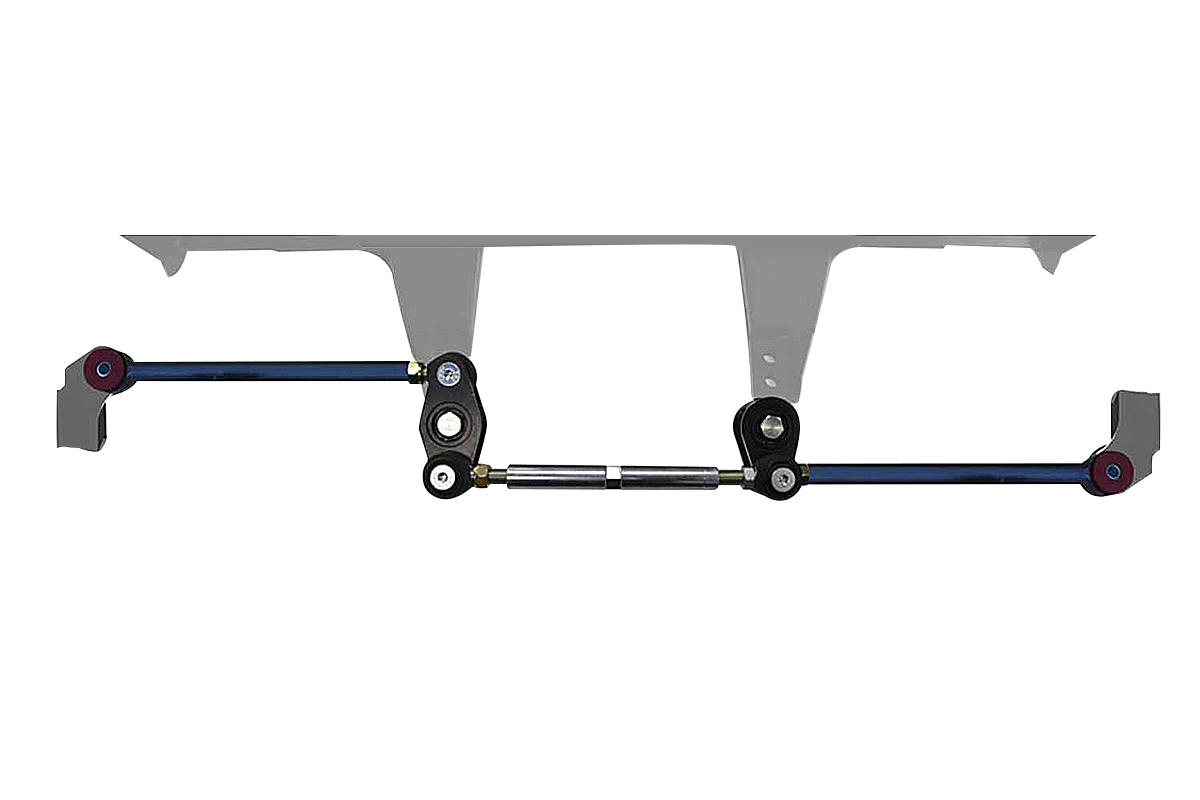

The RRS bolt-in 3-Link features better geometry than any factory four-link set-up. This superior geometry results in eliminated roll under-steer, accurate turn-in and superior steady-state cornering, which makes the car more neutrally balanced and endows it with more predictable handling.

RRS rear 3 – link suspension complete from AUD$4600 - 5 YEAR WARRANTY

Bolt-In 3-Link Rear Suspension

For performance applications, the RRS 3-Link system increases chassis beaming and torsion rigidity for faster suspension reaction time (for better feedback), greater torque handling capacity, optimum torque transference to the chassis and precise control over differential movements. It also allows wheels with up to a 5½-inch offset to be used.

Best of all, the modular design incorporates generous user-adjustable settings including; ride height, damper tuning, pinion angle, lateral differential location and roll centre height (for fine-tuning the vehicle’s handling characteristics). All of which results in better traction (for improved acceleration and braking) along with outstanding cornering ability.

-

Tyre Clearance

As the factory leaf spring system compresses, the differential housing can move forward as much as 60mm. When cornering (i.e. one side down one side up), this moves one side further forward than the other – which induces hideously undesirable roll under-steer. The RRS 3-Link is designed to limit this fore/aft movement of the differential housing to 15mm (throughout its travel) which substantially minimises roll under-steer. If your wheel well openings have been modified to accept very wide or very large diameter tyres that run close to the guard, you may experience guard fouling problems with the RRS 3-Link due to the different arc of travel the differential housing now moves through. That is to say; with the RRS 3-Link, the tyre will stay more centred in the wheel arch throughout the range of suspension travel.

-

Varying Tolerances

Every RRS bracket is laser cut to exact tolerances and all frames and cross-members are jig welded in precision fixtures for steadfast consistency. In comparison, Ford’s original construction tolerances were quite loose, with variances of up to 8mm (5/16”) being observed. Also, collision and rust repairs can result in considerable movement of structural members. A couple of examples of the typical inaccuracies introduced by rust repair work include; lateral shrinkage when adding new floor sections and lateral spreading when adding a new tunnel. New floors often entail new seat boxes. Many installers use the seat mounting holes in the seat boxes to align the replacement floor sections – this is hideously inaccurate.

-

RRS Built-in Tolerance

To accommodate these unknown variables, all RRS mounts and frames are manufactured for ease of fitment and allow for significant chassis variations. However, they may require jacking into the location or some deft persuasion with a plastic-faced hammer or heavy rubber mallet.

The RRS Advantage

- Superior ride & outstanding cornering ability.

- Drastically improved suspension geometry.

- Reduced roll understeer.

- User-adjustable ride height.

- Adjustable damper tuning.

- Eliminates dive under hard braking.

- Reduces rear-end squat for superior acceleration.

- Neutral handling characteristics make the vehicle a pleasure to drive.

- Able to handle high torque loads.

- Improved stability of chassis.

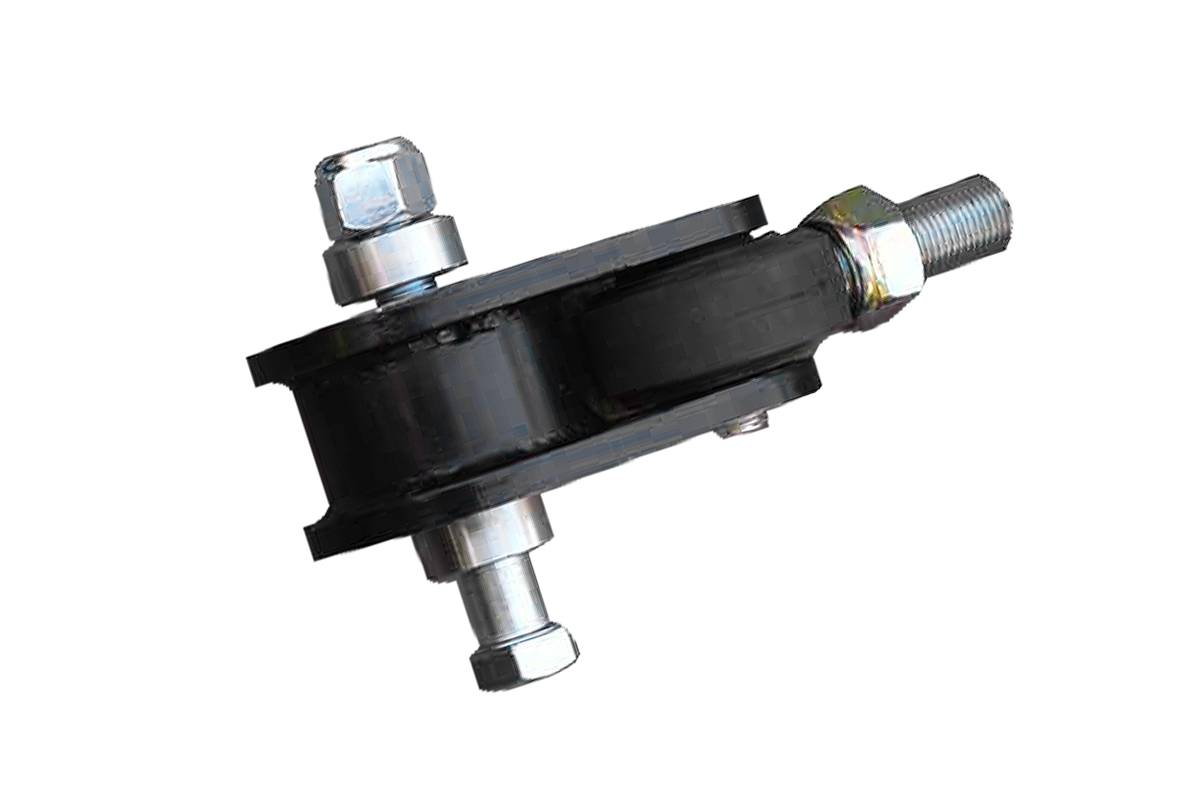

- Bolted in, no cutting or welding.

In-Depth RRS Trans-Am 3-Link Benefits

- As the factory leaf spring system compresses, the differential housing can move forward as much as 60mm.

- When cornering (i.e. one side down one side up), this moves one side further forward than the other – which induces roll under-steer.

- The RRS 3-Link is designed to limit this fore/aft movement of the differential housing to 15mm (throughout its travel) which substantially minimizes roll under-steer.

- The extremely torque arm the RRS 3-Link boasts drastically improves the suspension geometry over the horribly wrong factory leaf spring set-up.

- The RRS 3 Link rear suspension system boasts dramatically improved suspension geometry over the inferior factory leaf spring set up.

- The superior geometry of the RRS 3 Link results in a drastically reduced roll under-steer, accurate turn in and firm flat cornering.

- The RRS 3 link makes the handling of the car more neutrally balanced and endows the car with predictable handling.

- The RRS 3 Link system increases chassis beaming and torsion rigidity for faster suspension reaction time allowing instantaneous feedback.

- RRS has designed the torque arm and cross member to handle up to 1000ft/lbs of torque

- User adjustable settings including ride height, shock damper tuning, pinion angle, lateral differential location and roll centre height

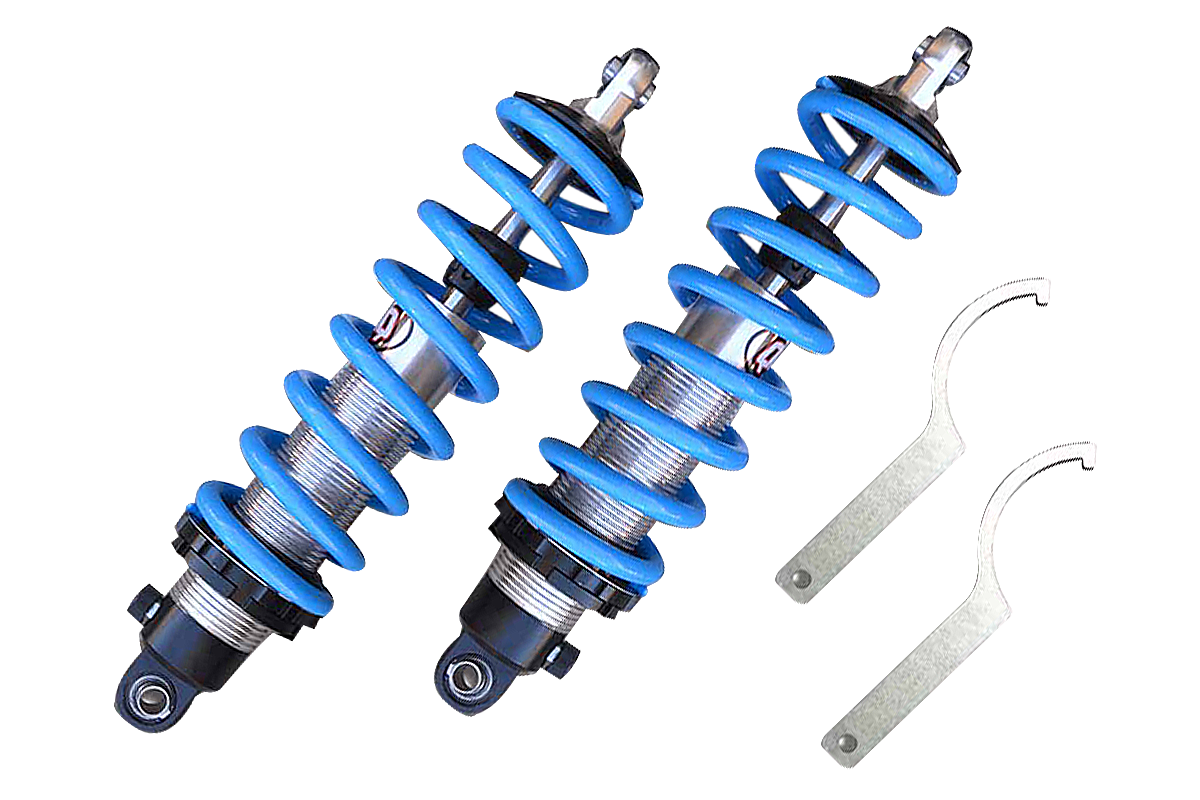

- Quality chrome silicon steel springs.

- All hardware and detailed instruction supplied for easy bolt-in installation.

Trans-Am 3-Link Installation Guide

Feb 26, 2019

Applications

-

XK-XP Falcon

Button -

XR-XY Falcon

Button -

XA-XC Falcon

Button -

XD-XH Falcon

Button -

Compact Fairlane FB FC FD

Button -

ZA-ZD Fairlane

Button -

ZF-ZH Fairlane

Button -

ZJ-ZL Fairlane

Button -

64½-66 Mustang

Button -

67-68 Mustang

Button -

69-70 Mustang

Button -

71-73 Mustang

Button -

60-65 US Falcon

Button -

66-70 US Falcon

Button -

62-65 US Fairlane

Button -

66-70 US Fairlane

Button -

70-77 Maverick

Button -

66-70 Torino

Button -

60-65 Comet

Button -

66-69 Comet

Button -

71-77 Comet

Button -

68-71 Montego

Button -

67-70 Cougar

Button

Trans-Am 3 Link

How To Get A Quote

We can provide door to door freight. Fill out below to get a quote.

GET A PRODUCT QUOTE

We will get back to you as soon as possible.

Please try again later.

Warranty & Product Guarantee

All RRS products go through thorough testing and analysis. It is our guarantee that all of our products, if installed correctly, will make your vehicle safer, stronger, and outperform the original product.

Ready to Take Your Classic to the Next Level?

If you have any questions, concerns, or need any parts advice for your classic ride, please don’t hesitate to reach out to the RRS team. We’re always happy to assist!

International leaders in bolt-in coil-over suspension and bolt-in rack and pinion steering systems for classic Mustang, Falcon, Fairlane, Maverick, Torino, Cougar, Comet, and other Ford classics.

Helpful Links

Sign up for the latest product releases and news.

Products

List of Services

-

Trans-Am 3 Link Rear SuspensionTrans-Am 3 Link Rear Suspension

The RRS bolt-in 3-Link rear suspension features better geometry than any factory four-link set-up.

-

RRS GT6 Rack & PinionRRS GT6 Rack & Pinion

The RRS GT6 rack and pinion steering system offers a lightning-fast ratio while retaining seamless lock-to-lock performance.

-

Coil-Over Front SuspensionCoil-Over Front Suspension

The RRS bolt-in coil-over front suspension kits offer superior performance and functionality advantage over competitors' products.

-

Brake Booster & Master Cylinder Kit (Under Dash)Brake Booster & Master Cylinder Kit (Under Dash)

The RRS Under Dash Power Brake Booster/Master Cylinder Kit has a truly universal application for manual or automatic right or left-hand drives.

-

Front Brake PackagesFront Brake Packages

RRS offers a comprehensive range of front brake options to suit all driving needs and budgets.

-

Shock Tower NotchingShock Tower Notching

The RRS shock tower notching kit is an optional system that will increase the distance between your shock towers by up to 11 inches.

-

Tie Rod Adjuster SleevesTie Rod Adjuster Sleeves

The RRS tie rod adjuster sleeve was designed to overcome the inferior factory adjustment system.

-

Drum in Disc Rear Brake Upgrade KitDrum in Disc Rear Brake Upgrade Kit

The versatile modular design of the RRS drum in disc brake rear conversion will work with all Ford 9" differentials and wheel sizes 14" to 20".

-

Barra Engine SwapsBarra Engine Swaps

RRS offers a complete Barra engine conversion for your early classic Ford. The engine swap includes engine mounts, specific-fit headers, plug-and-play wiring harness, and flash factory ECU.

-

Shotgun Engine SwapsShotgun Engine Swaps

RRS offers a comprehensive Shotgun engine conversion for your early classic Ford.

-

Coyote Engine SwapsCoyote Engine Swaps

RRS offers an all-inclusive Coyote engine conversion for your early classic Ford.

-

Grabber Engine MountsGrabber Engine Mounts

RRS has multiple engine mount options for Modular V8 motors, Typhoon turbo motors, and big block motors.

-

Strut Rod Adjuster KitsStrut Rod Adjuster Kits

Enhance your classic Ford’s performance with RRS’s strut rod adjuster kits.

-

Le Mans Lower Control ArmsLe Mans Lower Control Arms

The RRS Le Mans forged aluminium lower control arms have been developed to give your classic Ford the best performance.

-

Reinforced Lower Control ArmsReinforced Lower Control Arms

The RRS Reinforced Lower Control Arm has been developed to give your classic Ford the best performance.

-

Daytona Strut BraceDaytona Strut Brace

The RRS Daytona shock tower strut brace addresses the problem of classic Ford shock towers flexing under hard cornering.

-

Billet Top CapsBillet Top Caps

The RRS billet aluminium top caps will provide a show-quality finish to your RRS strut-equipped engine bay.

-

Pursuit ColumnPursuit Column

The RRS pursuit column is a collapsible and tilt-adjustable steering column that allows engine-modified vehicles to be VSB14 compliant.